A brine calculator is a versatile tool. It helps you achieve precise salt-to-water ratios. This tool is vital for effective de-icing. You can create the perfect salt brine. It also supports successful food preservation. Think of fermentation or brining meats. Accurate calculations ensure optimal results. They guarantee safety and efficiency. Proper salt concentration in your brine is key. This prevents issues. You need the right amount of salt in your brine. This applies to all uses. A precise salt brine makes all the difference.

Brine Calculator

Understanding Your Brine Calculator

A brine calculator simplifies complex ratio calculations. It helps you create the perfect brine every time. This tool takes the guesswork out of mixing salt and water. You get consistent results for all your projects.

Why Precision Matters in Brine Ratios

Precision in brine ratios is very important. Too little salt in your brine can make it ineffective. For de-icing, weak salt brine will not melt ice well. For food, insufficient salt can lead to spoilage. It fails to preserve food safely. Too much salt also causes problems. An overly strong salt brine can damage concrete or plants. In food, too much salt can make items inedible. It can also change textures negatively. Accurate salt levels ensure safety and desired outcomes.

Online Tools and Features of a Brine Calculator

Online brine calculator tools are easy to use. They provide a simple interface. You input your desired outcomes. The calculator then tells you exact amounts. Features often include fields for target salt percentages. You can specify the total volume of brine you need. Some tools even suggest different salt types. They make creating the right brine simple and quick.

Key Variables for Accurate Brine Calculation

To get accurate results from your brine calculator, you need specific information. You must provide key variables. These include:

Meat weight

Target salt percentage

Whether curing salt is included (this is optional and depends on your project)

For brines: a water percentage that truly submerges the meat

Measuring inputs accurately is crucial. This is especially true for the water volume. You need enough water to cover the meat in its container. To do this, place the meat into its intended container. Add just enough cold water to cover it. Then, measure that water. Set the brine calculator’s water percentage to match this measured volume. This ensures all spice and salt percentages are based on a real number, not a guess. This method guarantees your brine has the correct salt concentration.

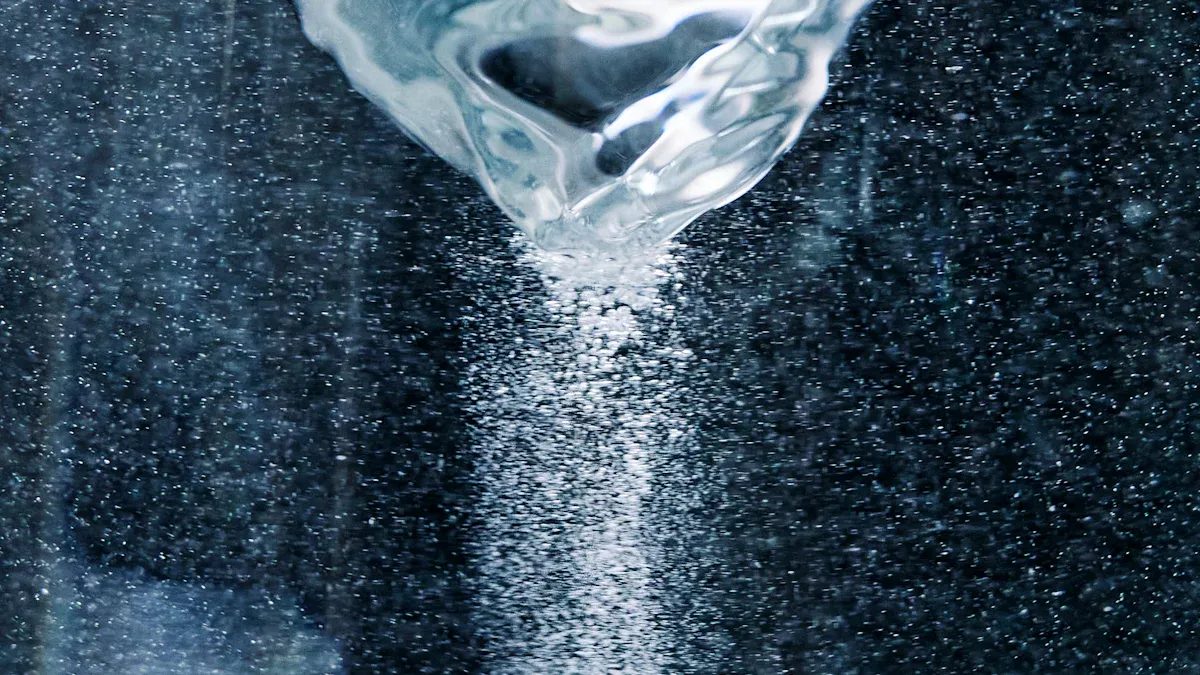

Crafting Effective Salt Brine for De-icing

You can make your winter maintenance much easier with a well-prepared salt brine. This section focuses on using brine specifically for de-icing. You will learn how to create an effective salt brine mixture and understand why it works better than solid salt.

Optimal Salt Brine Concentration for De-icing

Getting the right concentration for your salt brine is very important. For the best snow and ice melting performance, you should aim for a salt concentration of 23.3%. If your salt brine has too much salt, it can actually become less effective in very cold weather. This happens because a higher concentration can raise the melting temperature, making it harder to melt ice. It also increases the risk of ice refreezing. On the other hand, if your salt brine has too little salt, it will not melt ice and snow well. This can also lead to refreezing and unsafe conditions. You need this precise balance for your brine to work best.

Benefits of Brine Over Solid Salt

Using brine for de-icing offers many advantages over spreading solid salt. Brine is often a better choice for the environment and your wallet.

Solid salt can cause several problems:

Soil contamination: Melted ice carries salt into the soil. This can harm plants and degrade the soil quality.

Water contamination: Deicers can enter rivers and lakes. This impacts aquatic life and water quality. High salt levels can harm fish and other water creatures.

Infrastructure damage: The corrosive nature of some deicers can speed up the wear and tear of roads, bridges, and vehicles.

Plant damage: Too much salt in the soil can hurt plants. It disrupts their nutrient balance and makes it hard for them to absorb water.

Brine helps reduce these issues. Brine uses much less salt overall, sometimes as little as 25% of what granular applications use. This means less chloride ends up in rivers, lakes, and soil. Brine also sticks better to surfaces. This reduces runoff, unlike granular salt which easily gets pushed away. You can apply brine more accurately, which means less overspray onto plants or sidewalks. Many liquid salt mixtures also contain corrosion inhibitors. These help protect things like metal fixtures and concrete.

However, you should know that brine does not completely remove chloride pollution. It still uses salt as its main ingredient. One teaspoon of salt can permanently pollute five gallons of water. Salt-contaminated runoff can damage aquatic ecosystems. It can lead to rising chloride levels. This makes some lakes unable to support fish or aquatic life. Drinking water wells near roads and parking lots are also increasingly affected by salt pollution. Even organic brines can cause problems by introducing phosphorus into waterways. This can fuel harmful algal blooms. Calcium chloride, sometimes used in brines, can be just as harmful to aquatic organisms as sodium chloride.

Making De-icing Brine: A Step-by-Step Guide

Making your own de-icing brine is simple and can save you money. Many cities and organizations have seen big savings by switching to brine.

Entity | Start Year | Actions Taken | Salt Reduction | Cost Savings |

|---|---|---|---|---|

University of Minnesota, Twin Cities | 2006 | Began making salt brine and anti-icing; adopted other salt reduction BMPs. | 48% | $10,000 new equipment cost; $55,000 cost savings first year |

City of Waconia | 2010 | Switched from 1:1 sand:salt to straight salt & liquid anti-icing; calibration; equipment changes; use of air and pavement temperatures. | N/A | $8,600 yearly cost savings ($1.80 per lane-mile) |

City of Prior Lake | 2003-2010 | Upgraded to precision controllers & sanders; anti-icing & pre-wetting; use of ground temperatures, best available weather data; on-site pre-mix liquid & bulk-ingredient storage, mixing & transfer equipment; staff education. | 42% | $2,000 per event estimated cost savings |

City of Richfield | 2010 | All-staff training; yearly sander calibration; use of low-pavement-temp de-icers; road crown-only application; minor-arterial-road policy adjustments. | > 50% | $30,000 (2010-2011); $70,000 (2011-2012) |

Rice Creek Watershed District Cities | 2012-2013 | Staff training; purchased shared anti-icing equipment. | 32% | $26,400 in one winter |

City of Cottage Grove | 2011-2012 | Staff training. | Not available | $40,000 in one winter |

City of Shoreview | 2006 | Stopped using salt/sand mixture; moved to straight salt; equipped plow trucks with spreading controls, pre-wetting tanks, pavement sensors; used calcium chloride in pre-wetting tanks; annual training. | 44% since 2006 | $24,468 in 2014 |

City of Eagan | 2005 | Moved from 50/50 salt/sand mix to straight salt; eliminated purchase of safety grit; EPOKE technology; use AVL; pre-wet at spinner. | Not available | $70,000 annual savings |

Joe’s Lawn & Snow, Minneapolis | 2013-2014 | Owner & staff training; new spreader, temperature sensors; equipment calibration; use of temperature data; ongoing experimentation. | 50% | $770 estimated cost savings in 2014 (used 9 tons instead of expected 20 tons) |

You can see the cost savings in this chart:

The Town of Hague, for example, cut its salt use by up to 70% and its winter maintenance budget by 50% after adopting brine. The Town of Peru saved $80,000 and reduced salt use by 50% in one winter. Washington County saved $300,000 and used 40% less salt in 2023. Anti-icing with brine before a storm can reduce salt use by up to 75% compared to spreading granular materials after an event. Pre-wetting granular salt with brine can also decrease the amount of salt you need by 20% to 30%.

Here is how you can make your own salt brine:

Gather your materials: You will need a large container, a way to stir, salt (rock salt or road salt works well), and water.

Measure your ingredients: Use your brine calculator to find the exact amounts of salt and water you need for a 23.3% concentration.

Mix the salt and water: Add the salt to the water in your container. Stir it well until the salt fully dissolves. This creates your salt brine mixture.

Test the concentration (optional but recommended): You can use a hydrometer to check the density of your brine. This confirms you have the correct salt concentration.

Store your brine: Keep your salt brine in a sealed container until you are ready to use it for snow and ice melting.

Brine for Food Preservation and Fermentation

You can use a brine calculator for many culinary projects. This tool helps you preserve food and create delicious fermented items. It ensures you get the right salt concentration every time. This section explores how you use brine for wet brining, dry brining, and lacto-fermentation.

Wet Brining Meats and Vegetables

Wet brining involves soaking food in a salt brine solution. This process adds moisture and flavor to meats. It also helps tenderize them. For vegetables, wet brining prepares them for fermentation or simply enhances their taste. You can brine poultry, pork, or even tough cuts of beef. Vegetables like carrots, green beans, and asparagus also benefit from a quick brine.

You need precise salt-to-water ratios for effective wet brining. A brine calculator helps you achieve this. Here are common ratios for brining meats:

Brining Duration | Salt-to-Water Ratio (Morton Coarse Kosher Salt to Water) |

|---|---|

4 to 5 hours | 1 cup to 1 gallon |

Overnight (up to 14 hours) | ½ cup to 1 gallon |

You simply mix the salt with water to create your brine. Ensure the salt fully dissolves. Then, submerge your food in the salt brine. The food absorbs the salt and water, resulting in a juicier, more flavorful product.

Dry Brining Techniques and Calculations

Dry brining is different from wet brining. You apply salt directly to the surface of the food. You do not add any water. The salt draws out moisture from the food. This moisture then mixes with the salt to form a concentrated brine on the surface. The food reabsorbs this flavorful liquid. This process tenderizes the meat and enhances its natural flavors.

You must use the correct amount of salt for dry brining. Too much salt makes the food overly salty. Too little salt will not achieve the desired effect. The amount of salt you use depends on the size of the food. A small fish fillet needs less salt than a large rib roast.

For Kosher salt, use approximately 1/2 teaspoon per pound of meat.

For finer table salt, use approximately 1/4 teaspoon per pound of meat. This prevents over-salting.

You should spread the salt evenly across all surfaces. A brine calculator helps you determine the exact amount of salt for your specific cut of meat. This ensures perfect seasoning every time.

Lacto-Fermentation with Precise Brine

Lacto-fermentation uses a salt brine to create an environment where beneficial bacteria thrive. These bacteria convert sugars into lactic acid. This acid preserves the food and gives it a distinct tangy flavor. You can ferment many vegetables, including cabbage for sauerkraut, cucumbers for pickles, and various ingredients for kimchi.

The salt concentration in your brine is crucial for successful fermentation. It inhibits harmful bacteria while allowing lactic acid bacteria to grow. A precise salt brine ensures safety and consistent results.

For cabbage, a 2% to 2.5% salt concentration is common. This range helps achieve optimal crunchiness and good lactic acid production.

For cucumbers, a 3.5% brine is often preferred. This concentration results in firm, crunchy pickles after about 21-25 days of fermentation at 72°F. An initial test with a 5% brine was too salty.

You can achieve an approximate 2.5% total salt concentration with a general method. First, weigh all your produce and the water you will use. Then, multiply that total weight by 2.5%. This calculation tells you the exact amount of salt to add. This method consistently gives you a 2.44% total salt concentration. This precise control over your salt brine is vital for delicious and safe fermented foods.

Different Salt Types and Their Impact

The type of salt you use affects your brining results. Different salts have different crystal sizes and mineral compositions. This impacts how they dissolve and how much salt you need by volume.

Kosher salt has larger, flaky crystals. It dissolves well and is popular for brining.

Table salt has fine crystals and often contains anti-caking agents. It is denser than kosher salt, so you use less by volume.

Sea salt varies in crystal size and mineral content. This can affect flavor.

Pickling salt is fine-grained and contains no anti-caking agents. This makes it ideal for clear brines.

You must adjust your measurements based on the salt type. A brine calculator can help you convert between different salt types. This ensures you always achieve the correct salt concentration. The right salt choice contributes to the final taste and texture of your preserved foods.

The Science Behind Brine Effectiveness

You use brine for de-icing or food preservation. Understanding the science behind it helps you get the best results. This section explains how brine works.

Eutectic Point and Freezing Point Depression

A salt solution lowers the freezing point of water. This is called freezing point depression. The eutectic point is the lowest temperature a salt solution stays liquid. For sodium chloride, this point is about -6°F (-21°C). This happens with a 23% salt concentration. For calcium chloride, the eutectic point is much lower, around -60°F (-51°C). This needs about 30% calcium chloride.

You might think a salt brine works down to its eutectic point. However, real-world conditions change things. Dilution from snow or ice affects performance. Pavement and air temperatures also differ. Precipitation rates and surface contaminants like oil play a role.

Material | Eutectic Temperature | Lowest Practical Temperature |

|---|---|---|

Calcium Chloride | -59°F | -25°F |

Magnesium Chloride | -28°F | +5°F |

Sodium Chloride | -6°F | +20°F |

Potassium Chloride | +12°F | +25°F |

Urea | +11°F | +25°F |

Osmosis and Microbial Control in Food Brine

Your food brine works by osmosis. This process moves water through cell membranes. Bacteria need water to live and grow. A strong salt solution pulls water out of bacterial cells. This dehydrates them. It stops them from feeding and reproducing. Fresh foods have high water activity, around 0.99. Salt lowers this water activity. It draws water out of the food. Lowering water activity to 0.91 stops most bacteria. This prevents decay and spoilage.

Impact of Incorrect Brine Concentrations

Using too little salt in your food brine creates risks. Low salt levels (between 1% and 2.5%) need other preservatives. Without enough salt, harmful bacteria can grow. Pathogens like Staphylococcus aureus can thrive. This causes food spoilage and health risks. Your brine must have the correct salt level for safety.

On the other hand, too much salt also causes problems. A high salt diet can lead to serious health issues. You might experience high blood pressure. This increases your risk for heart disease and stroke. Excess salt makes you retain water. This causes bloating and swelling. It can also harm your kidneys over time. Your salt brine needs to be just right.

Practical Tips for Brine Application

You can get the best results from your brine by applying and storing it correctly. This section gives you actionable advice. You will learn how to handle brine for de-icing and food.

When and How to Apply De-icing Brine

Apply de-icing brine before a storm. This prevents ice from bonding to surfaces. You can also use brine after light snow. This helps with snow and ice melting. The amount of salt brine you use depends on conditions.

Condition | Application Rate (Gallons per Acre) |

|---|---|

Light snow pack or glaze | 70-90 |

Heavy snow pack or bad ice | 100-120 |

Post-treatment (general) | 70-100 |

Liquid de-icing brine works well on both concrete and asphalt surfaces. Studies are ongoing to explore its full effects on these materials. You apply brine using sprayers. These sprayers attach to vehicles. Ensure even coverage for the best results.

Storing and Handling Food Brine

Proper storage keeps your food brine safe and effective. Always store food brine in clean, airtight containers. Keep it in the refrigerator. This prevents bacterial growth. You can reuse some brines, but check for cloudiness or off-smells. If you see these, discard the brine. Always use clean utensils when handling food brine. This avoids contamination. Your brine needs careful handling for food safety.

Additives for Enhanced Brine Performance

You can improve your salt brine with additives. These substances boost its effectiveness.

Sugars and Carbohydrates: These act as tackifiers. They make the brine stick better to surfaces. This stops the brine from blowing away. You can apply brine earlier before a storm.

Calcium Chloride and Magnesium Chloride: These lower the freezing point of salt brine. Standard salt brine melts ice down to about 15-20º Fahrenheit. These additives help it work in colder temperatures.

Additives also offer other benefits. They reduce the amount of de-icing brine you need. They increase overall de-icing performance. Some additives reduce corrosion. They also increase surface stickiness and reduce runoff. This makes your brine more efficient.

A brine calculator is an essential tool. It helps you achieve precise salt ratios for de-icing and food preparation. Accurate salt calculations ensure safety, efficiency, and desired outcomes. You get perfect salt levels every time. Leverage a brine calculator to master your brine needs. This applies to winter maintenance or culinary creations.

FAQ

What is the best salt concentration for de-icing brine?

You should aim for a 23.3% salt concentration. This mixture provides the lowest freezing point for sodium chloride. It effectively melts ice and snow. Too much or too little salt makes it less efficient.

Why do I need a brine calculator for food?

A brine calculator ensures precise salt ratios. This precision is vital for food safety. It prevents spoilage and achieves desired flavors and textures. Accurate measurements guarantee successful preservation and fermentation.

What is the main difference between wet and dry brining?

Wet brining involves soaking food in a salt-water solution. Dry brining means you apply salt directly to the food’s surface. Both methods enhance flavor and moisture. They use different salt application techniques.

Does the type of salt affect my brining results?

Yes, salt type matters. Different salts have varying crystal sizes. This impacts how much you need by volume. For example, you use less fine table salt than flaky Kosher salt. Adjust your measurements accordingly. 🧂